Brake Disc Drum Lathe Machine Equipment

Brake Disc/Drum Lathe Machine Equipment adopts big base with the strong rigidity, which is mainly used to repair the brake disc and drum and brake shoes of large trucks. There are a variety of special accessories for users to choose, which will meet the needs of different models of vehicles. Brake Disc/Drum Lathe Machine Equipment is the ideal Automotive Service for Brake Disc/Drum and Car Maintenance Lathe for Brake Disc/Drum for bus companies and large and medium-sized car repair shops.

Brake Disc Drum Lathe Machine Equipment Introduction

Brake Disc/Drum Lathe Machine Equipment adopts big base with the strong rigidity, which is mainly used to repair the brake disc and drum and brake shoes of large trucks. There are a variety of special accessories for users to choose, which will meet the needs of different models of vehicles. Brake Disc/Drum Lathe Machine Equipment is the ideal Automotive Service for Brake Disc/Drum and Car Maintenance Lathe for Brake Disc/Drum for bus companies and large and medium-sized car repair shops.

Product Features

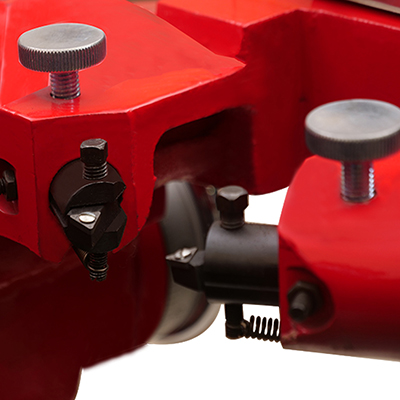

1. Limit-stop structure on the twin cutter ensures safety.

2. Equipped with standard clamps, which is easy and convenient to fix hubless brake drum.

3. Standard chuck makes it easy to clamp hubless brake drum.

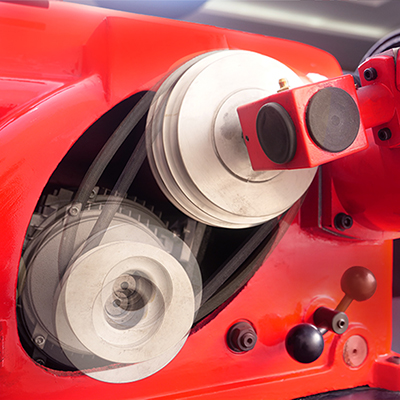

4. Spindle speed can be controlled by the frequency changer and can be adjusted within a certain range even not stopping the car.

5. Special adapters can be customized. Special twin cutter will be used when repairing the disc of large trucks and buses.

Main Specifications

Spindle Travel | 9.875” (251mm) | Spindle Speed | 70,88,118 rpm |

Spindle Feed Speed | 0.002”(0.05mm)-0.02” (0.5mm) Rev | Cross Feed Speed | 0.002”(0.05mm)-0.01” (0.25mm) Rev |

Handwheel Graduations | 0.002”(0.05mm) | Rotor Diameter | 7”-18” (180-457mm) |

Rotor Thickness | 2.85” (73mm) | Drum Diameter | 6”-17.7” (152-450mm) |

Drum Depth | 9.875”(251mm) | Motor | 110V/220V/380V 50/60Hz |

Gross Weight | 325KG | Dimension | 1130×1030×1150 mm |

Product Details

1. A Set of Standard Adapters

| Twin Cutter | 1 | Bend Wrench | 1 | Spring | 1 |

| Boring Bar Assembly | 1 | Taper Cone(45×70mm) | 1 | Nut | 1 |

| Arbor with Nut and Combination Washer | 1 | Taper Cone(59×75mm) | 1 | Small Spacer (133mm) | 1 |

| A Lamp with Three Batteries | 1 | Taper Cone(66×82mm) | 1 | Big Spacer (171.5mm) | 1 |

| Plastic Safety Shield | 1 | Taper Cone(74×90mm) | 1 | Small Adapter (133mm) | 1 |

| Open End Wrench (27-30mm) | 1 | Taper Cone(90×145mm) | 1 | Big Adapter (171.5mm) | 1 |

| Square Wrench | 1 | Spacer | 3 | Step Adapter | 1 |

| Belt | 1 | Hub Localize | 1 | Clamp(94mm) | 2 |

| Cutting Bar | 3 | Localizer Small Taper Cone | 1 | Clamp(116mm) | 2 |

| Silencing Belt for Rotor and Drum | 2 | Localizer Big Taper Cone | 1 | Clamp(146mm) | 2 |

2. Disc Repairing Cutters

3. Drum Boring Cutter

4. Cutting Tips

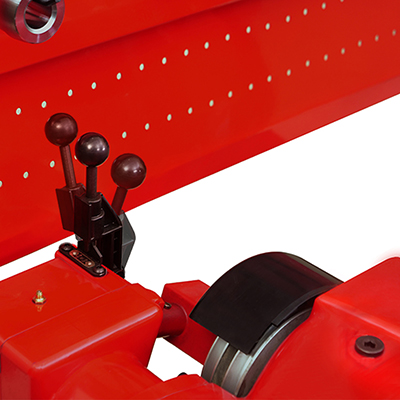

5. Fast and Slow Setting

6. Spindle Speed Adjustment